ROASTERS

Prometheus

craft a flavour from the flames

About us

- Prometheus offers innovative solutions for coffee shops and roasteries.

- We analysed the specialty coffee market and created the world’s first convection-conducting roaster.

Roasters

Features

of our roasters

1

Air heating system

- Stable roast regardless of weather, temperature, humidity, and season.

- Up to 25% fuel savings thanks to air preheating. Use only 2 litres per hour on a 35-kW burner!

2

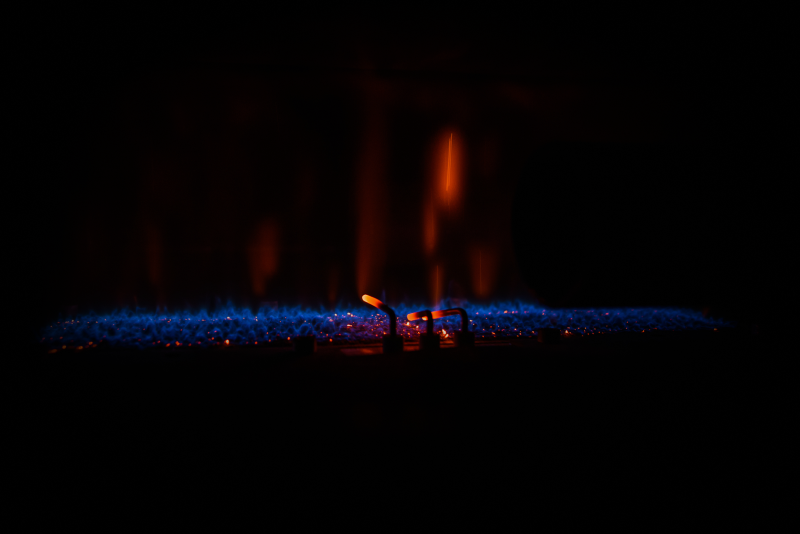

Burner

- The 1,000°C catalyst glow temperature guarantees the waste-free combustion of products.

- Almost complete absence of exhaust gases in coffee (CO2 — 12%, Nox <10 ppm, CO <10 ppm).

- Flame modulation — 5 kW to 36 kW. The burner does not extinguish — at 5 kW the infrared mode starts automatically.

3

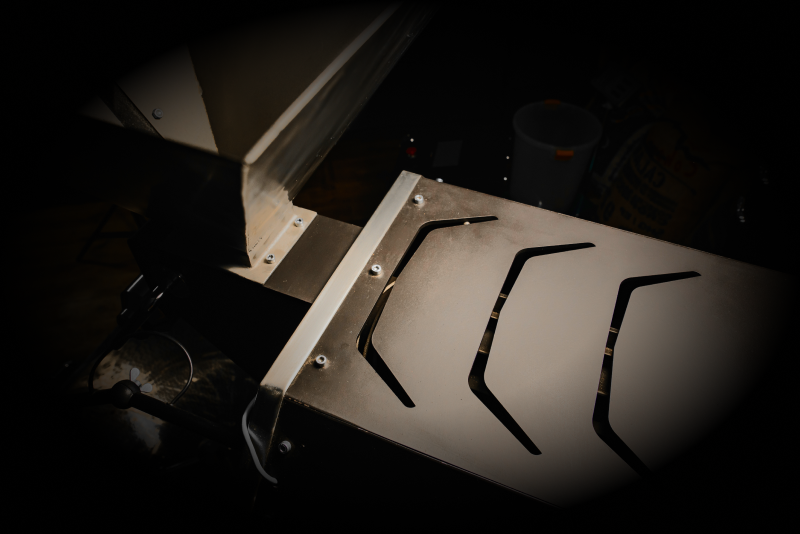

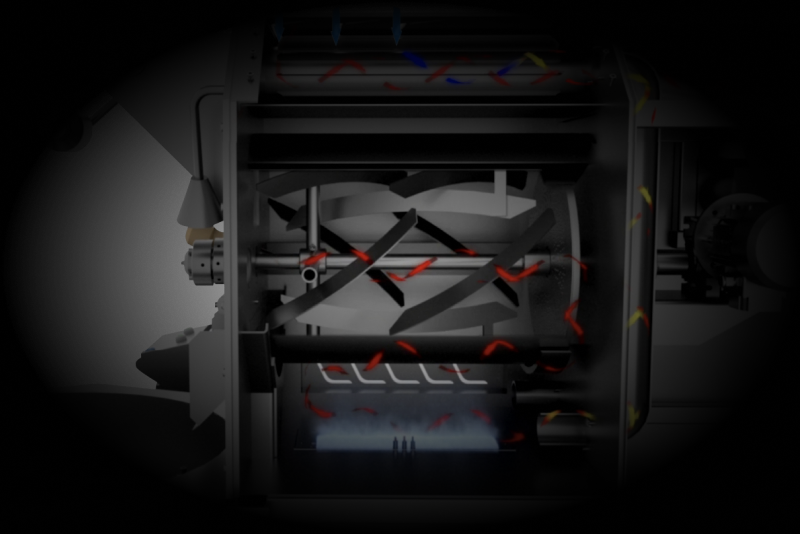

Drum

- The outer wall is made of heat-resistant stainless steel with titanium.

- The inner wall is made of food-grade stainless steel.

- The perforated back wall provides excellent convection.

- Three-level paddles intensively mix the coffee both circumferentially and in a plane.

4

Air Flow

- The Prometheus roaster combines the advantages of convection and conduction roasters. Thanks to our Air Preheating technology, you get an evenly roasted and organic coffee with a rich taste.

- Air flow control regardless of the condition of your chimney and weather conditions in automatic and manual modes.

5

Auto cooling

- The ability to automatically program the cooling process, its intensity, and the interval and speed of rotation of the blades.

- An infra-red thermocouple takes readings and stops the cooling process when the required temperature is reached. When the coffee is unloaded, the mixer blades stop.

The benefits

of Air - Preheating

prometheus roasters

Flame modulation

Burner stability

Roast stability

Coffee fullness

Roasting stability independently of the external factors impact (air temperature, humidity, atmospheric pressure)

CO2, NOX and CO emissions

low

high

minimum

The coffee is roasted only with hot air. The product does not come into contact with a hot surface. Uniform heating is provided by electric heating elements or a blowing gas burner.

The heated air from the heating chamber enters the roaster drum or fry chamber. The temperature is controlled by varying the Air Flow power and mixing in cold air.

The heated air from the heating chamber enters the roaster drum or fry chamber. The temperature is controlled by varying the Air Flow power and mixing in cold air.

Coffee is roasted only with the heated roaster drum walls, under which there is an atmospheric burner.

The temperature is controlled by changing the Air Flow power and flame modulation.

The temperature is controlled by changing the Air Flow power and flame modulation.

Coffee can be roasted both with hot air and with the heated walls of the roaster drum. The Premix flat burner under the drum guarantees even heating.

Hot air is blown in through the perforated back wall. Energy is transferred between the walls, ensuring a stable roasting process.

The temperature is controlled by changing the Air Flow power and flame modulation.

Hot air is blown in through the perforated back wall. Energy is transferred between the walls, ensuring a stable roasting process.

The temperature is controlled by changing the Air Flow power and flame modulation.

Forced air injection creates a gas-air mixture. The nozzle is in the air heating chamber.

The burner operates in on/off mode. The flame is most often not modulated, but it can have several modes.

Temperature control is performed only by mixing cold air into the drum.

The burner operates in on/off mode. The flame is most often not modulated, but it can have several modes.

Temperature control is performed only by mixing cold air into the drum.

Atmospheric burners are located under the drum and take in air in free mode. Gas may not burn out and can enter the fry.

When modulating a flame, you are limited to 3−4 degrees or 5% steps. When the Air Flow setting is low, the flame may be unstable.

When modulating a flame, you are limited to 3−4 degrees or 5% steps. When the Air Flow setting is low, the flame may be unstable.

The burner forcibly blows air and creates a gas-air mixture. It passes through heat-resistant metal fibre and is heated to 1,000 °C.

The burner is located under the drum, providing excellent conduction and convection performance.

The flame is guaranteed not to go out. You can modulate it within 1% without adding cold air.

The burner is located under the drum, providing excellent conduction and convection performance.

The flame is guaranteed not to go out. You can modulate it within 1% without adding cold air.

We created an unique machine that combines the advantages of hotair and conducting roasters

Accessories

Service

Contacts

To get the consultation